Note:

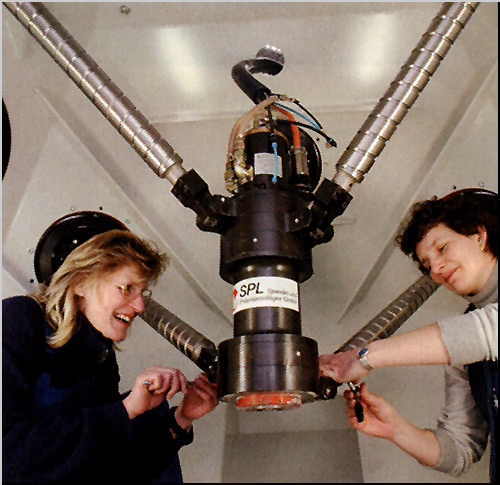

For this interesting project, A.MANNESMANN delivered four AM ball screws TK 63 x 40 x 8 in a design as a positioning spindle with a driven nut.

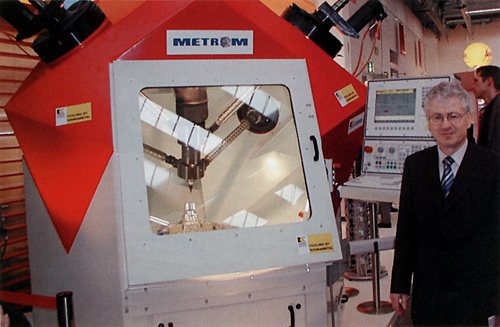

A futuristic-looking machine tool design for machining centers comes from Chemnitz and causes a sensation at every trade fair - most recently at the prototypes and mold-making trade fair “Euromold” in Frankfurt: The P 800 M milling center from Metrom looks like a space capsule already due to its spherical shape: It stands like a design object in the room as an “icosahedron,” a twenty-sided (and twelve-cornered) housing capsule made of identical and equilateral triangles. However, the interior is even more interesting to production engineers or a toolmaker and mold maker than the spectacular exterior of the advance developed machine: A parallel kinematics with spherical working spaces ensures the machining of workpieces and free-form surfaces from five sides in the hemispherical working area. Only the bearing surface of the machine rotary table remains inaccessible for machining.

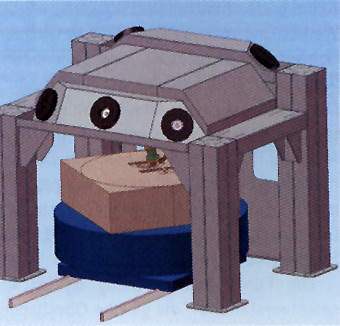

From a purely technical perspective, the Metrom machines are a parallel kinematic design, which is now being optimized for public use: The modular machines are available in two series, which can be easily adapted to user requirements. The machines are airy and lightweight compared to a conventional milling machine with a slow and bulky cross-table and provide the parallel kinematics with a brilliant comeback. In this machine design, a lightweight spindle is held in position from all directions in a highly dynamic way by five powerful arms made of solid ball screws: The work spindle is moved here not just by a few ball screws, as is found in the machine tables of conventional machine tools for positioning and moving: Protected by bellows, the solid ball screws stand in the space and protect the work spindle from five sides at the same time. With its tool, it can thus work independently in the space from all sides. In this way, elegant work movements are used to create a free-surface molded part from a metal or plastic blank that can be seen or to create a workpiece machined on all sides.

Sturdily supported on all sides, the work spindle is always brought and held in the correct machining position. Only the spindle moves in the space - otherwise nothing moves.

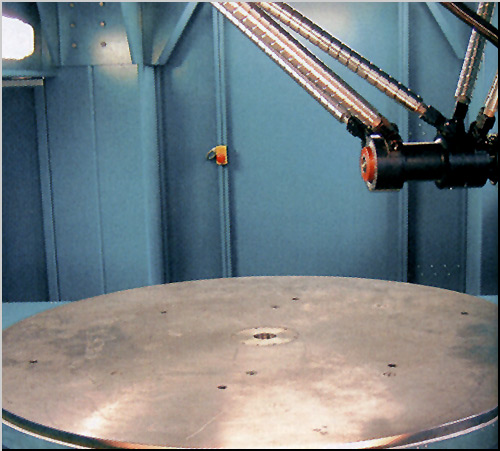

In the Metrom machine, the workpiece remains in place unmoved and is turned around an additional axis by no more than one rotary table in the current new design: Without inertia problems, stick-slip effect and centrifugal forces and without linear movement, at the most with one revolution around the vertical axis.

No large-volume and heavy machine parts or workpiece have to be accelerated and braked. No swivel axis has to be tilted in order to carry out lateral machining. Acceleration ramps and quick feed are forgotten. The lightweight work spindle sways and dances elegantly around the cube of the workpiece, always worked perpendicularly to the work surface in the ideal position, sometimes at 90 degrees and more to the side, grabbing slightly undercutting, sometimes from below if necessary. It is therefore far superior to any five-axis machining when it comes to maneuverability, dexterity, dynamics and the ideal position for the machining tool.

The five-sided machining is no problem in the spherical work space as is the same surface quality and accuracy as with conventional machine tools. During neutral machining tests, for example, average roughness depths of one and a half thousandths of a millimeter were determined. The natural prejudices of the first impression, the distrust of the new, lightweight and airy-looking design has to admittedly be overcome when you approach this machine: The sheet metal design is the housing and frame at the same time, it looks “spherical” and also has a spherical working space. Five gimbal-mounted ball screws protrude out of the sheet metal housing. The machining can be watched through portholes like on a washing machine.

From a technical point of view, the P 800 M from Metrom, which is the smaller of the two series, is a 4.5 ton milling center in the smallest of spaces: A sheet metal design like a space capsule, consisting of a twenty-sided polygon made of equal and equilateral triangles, optimally shaped. It encloses a working space with rotary table of 800 millimeters in diameter. Workpiece cubes with a meter diameter and 600 mm in height can thus be machined with a machine size of 2.3 x 2 x 2.5 meters. The “axes” work at an acceleration of 12m/s² with a repeat accuracy of three thousandths of a millimeter.

The almost free-floating work spindle, normally an HSC spindle with an HSK-63 mount, 24,000 revolutions and 14 kW drive power, is kept in the space by spindle carriers with flexible joint discs on hinge joints and by five strong struts made up of ball screws of 63 millimeters in diameter. The lightweight work spindle is all that has to be moved, accelerated and braked. It can be tilted to the side horizontally by more than 90 degrees, thus dwarfing any machine with a cross table and swivel axis. In this way it reaches almost any point in the machine space: With not only five, but rather an almost infinite number of degrees of freedom, it is flexible and mobile like a robot arm. With a rotary table and due to the side tilt of more than 90 degrees, a five-sided free-form surface machining is possible, even with undercuts

A quick control system is a natural condition for parallel kinematic machines and that is what the Metrom machine has to offer: Everything is monitored, regulated an controlled by the “Andronic 2000” control system with a block cycle time of 0.5 milliseconds, cycle times of 0.5 milliseconds and a convenient look-ahead function. It always knows where the tool currently is and calculates any position in the hemispherical work space. It of course takes care of the calculation of the additional rotary axis of the rotary table as a machine basis. The programming and operation are no different from conventional machines. It processes any existing NC program from standard CAM programming systems.

The machine that comes from the future is a space capsule with little space needed and a small amount of floorspace required. The renaissance of the parallel kinematics makes it future-proof. Anyone who cannot believe the work results, which are in no way inferior to those of a conventional machine, will be shown on their own workpiece in Chemnitz everything that the machine can do and how a presentable result can be achieved.

Anyone who wants to already have the technology of the future in their production today has to invest about EUR 250,000. In Germany, the only two-year old manufacturing company in Chemnitz with the managing director Dr.-Ing. Michael Schwaar, “spin-off” of a Fraunhofer company FhG, of course already found pioneer users for its milling centers. They were so convinced by the exclusive first machine that they bought it again.

METROM Mechatronische Maschinen GmbH

Annaberger Str. 240, 09125 Chemnitz

Tel.: 0371 5347-600, Fax: 0371 5347-601

E-mail infometromcom

www.metrom.com