Overview of Ball Screws for High-Speed Applications

To achieve very high travel speeds in high-speed applications, the ball screw must be capable of high speeds with large thread pitches. A very quiet operating behavior is indispensable, especially with these high dynamic requirements.

High Flexibility in Application

Although the continuous load in the high-speed range is comparatively low, very high short-term peak loads also act on the ball screw during the temporary change of the high accelerations or decelerations as well. So that the balls can roll without slipping and precisely in all operation phases, the preload and therefore the detachment force may need to be modified accordingly.

Application Areas

In addition to high-speed main spindles, machine tools, such as machining centers for high-speed cutting applications, require very dynamic feed axes to be able to produce highly precise workpieces in short cycle times. The high travel speeds minimize the non-productive times and allow for optimal machining processes. With the high dynamics of such feed axes, however, not only is the focus on the axial travel speed, but rather especially on a high acceleration and a high deceleration.

High-speed ball screws are used for extremely dynamic requirements. That is why they are designed to achieve extremely high travel speeds, especially for very high pitches. For this purpose, they effortlessly handle high-speed acceleration and deceleration, peak loads and also severe jerks.

The ball screws from A.MANNESMANN for high-speed applications are ideally equipped for these extreme challenges.

Economical advantages

- Lowest cost standard version

- Extremely high speeds

- High peak loads

- Low power loss

- Excellent energy efficiency

- High long-term durability / service life

- Maximum long-term precision

- Maximum possible machine availability

- Perfected wear resistance due to nitrided spindle

- Economical standard designs or custom production

Technical advantages

- Driven nut

- Minimum residual imbalance of the nut body (balancing quality Q2.5)

- Critical vibration speed determines the application limits (speed characteristic value of dn x n (nominal diameter x speed) < 220,000)

- High speeds (dn < 130,000)

- High axial travel speed

- High pitch

- High speeds

- High acceleration (up to over 20 m/s2) or deceleration

- High jerk (up to 1,000 m/s3)

- Lower continuous load

- Very quiet running behavior

- Increased preload

- High detachment force

- Very good dynamic behavior

- High precision and efficiency

- Very long service life

- High nut rigidity

- Low friction

- Low idle torque

- The highest power transmission rates

- Extremely high degree of efficiency (up to 98%)

Peak Values in Acceleration and Deceleration

In order to effectively realize acceleration phases, the acceleration is not constant, but rather its temporal course is determined via the jerk. This can briefly result in significant peak values in acceleration, which are well above the nominal values and allow the acceleration forces to rise extremely within a few milliseconds. The same applies for the deceleration.

Optimized for Maximum Short-Term Loads in All Operating Phases

AM precision ball screws for high-speed applications are specifically designed for these special requirements in order to also safely transfer the short-term high loads in all operation phases. During production, value is therefore placed on particularly quiet, low-vibration and smooth running behavior of the ball screw. They are therefore usually designed to be speed-optimized as a double nut with total deflection systems and increased preload. Larger thread pitches are normally used with these ball screws so that the operating speeds remain in a tolerable range, even with longer ballscrew shafts.

Parameters of the High-Speed Applications

The high-speed applications include all of the applications where fast-running ball screws (dn > 130,000) are used. Travel speeds of 150 m/min and accelerations of 20 m/s2 with jerk values of up to 1,000 m/s3 are still not absolute limit values depending on the mass to be moved and with optimally coordinated operating conditions for AM ball screws.

Safety Through Lubrication, Cooling and Monitoring

Through additional lubrication and cooling measures, such as the use of monitoring sensors directly on the ball screw, even the highest dynamic requirements can be met reliably over a long service life.

The speed characteristic value of dn x n (nominal diameter x speed) < 220,000 applies as a reference value for high-speed ball screws with driven nuts!

Standards and Custom-Made Production

A.MANNESMANN supplies these precision ball screws for high-speed applications in the nominal diameters of 25, 32, 40, 50 and 63 mm with all the common thread pitches and in the accuracy classes better than IT 5.

Of course as a manufacturer, we also produce special diameters. Please just send us your inquiry.

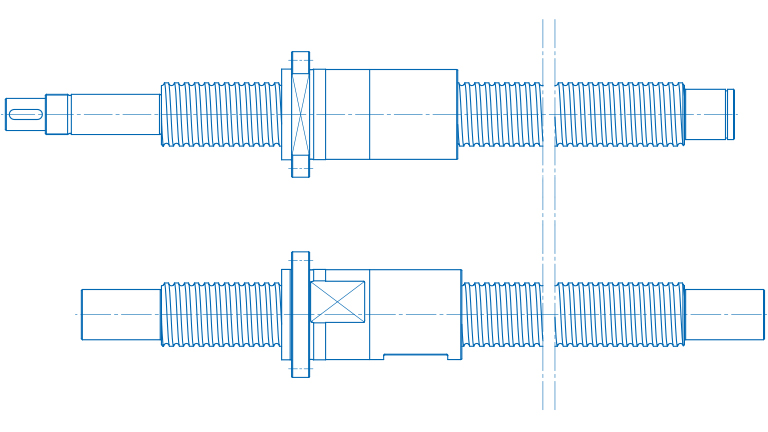

Driven nut and spindle on a ball screw

Characteristic Values of the Ball Screws

In addition to the dimensions, the load ratings, the nut rigidity and the idle torque are the classifying characteristic values of ball screws. The load ratings describe the load bearing capacities of the ball screw during movement (dynamic) and at rest (static). The dynamic load rating is also the basis for calculating the service life.

The nut rigidity is the measure for the axial force, which is required for deformation in the ball transition contact. The idle torque is the characteristic value for the internal system friction. Together with the nut rigidity, the preload can also be closed via the idle torque.

You will find the characteristic values in the technical data sheet of each ball screw.

Rotatory Mass Moment of Inertia

The rotatory mass moment of inertia (Js) of the spindle is usually required for designing the motor. With driven solid spindles, this (with a good approximation neglecting the thread geometry) corresponds to the cylindrical spindle body with respect to its axis of rotation.

Here the ball contact diameter dc on the spindle with the 4th power, the spindle length ls and the density of the spindle material rs are decisive. The mass moment of inertia Js is usually specified in kgcm2. If the rotatory mass moment of inertia Js is related to the spindle length of one meter, then it can easily be converted by multiplying the ratio of the existing spindle length with one meter.

Spindle Torsion

The spindle is normally driven by a motor. The motor's drive torque is guided through the spindle to the nut and there converts into an axial force. In the slim spindle, this results in a torsion due to the torsional moment that exists. The torsion length, the torsion angle and therefore also the torsional rigidity depend on the axial nut position on the spindle. Since this can change variably in operation due to the axial displacement, the torsional rigidity is also not a constant characteristic value.

The maximum torsional stress of the spindle (can usually also be assumed to be a circular full cross-section) can be determined from the torsional moment or torque (T) and from the polar modulus of resistance of the ball screw spindle (Wps) or the spindle diameter.

The torsion angle (torsional angle) is dependent on the spindle length or on the position (I) where the torque acts and on the shear modulus (G) of the spindle material. To calculate the torsional angle, the moment of area of the 2nd order (Ips) and the torsional moment (T) are also required.

Since the effective position (I) varies depending on the axial travel movement of the nut, the torsional angle (j) is also not a constant value, but rather is a function of the length (I). However, torsional angle is also directly dependent on the time variation of the effective torque, whereby it is also to be seen as a function of time. That is why torsional vibrations that temporally vary depending on the torsion are created, which also act in the axial direction through the ball screw.

Tensile and Compressive Load

In addition to the torsional load, a driven spindle is mainly loaded by tension or pressure. In both cases, the tensile or compressive strength of the spindle are the load limit values.

When evaluating the load, it is important to take the correct "smallest" spindle cross section into account. Only the cross-section that lies in the spindle's distribution of forces is relevant for determining the tension. With the tensile load, the determining spindle cross section usually does not lie in the area of the ball screw, but rather in the area of the mounting thread of the bearings. The buckling stability is also to be noted, since there is a risk of buckling in the event of a compressive load on particularly long spindles.

Characteristic Value Calculations

As part of our service, we offer you the calculation of the most important characteristic values. We would like to support you in your planning from an early stage.

Get in touch with us by sending an e-mail to salesamannesmannde with the subject "Characteristic value calculation" or by phoning us at +49 2191 989-0 and give us the following parameters of your desired ball screw:

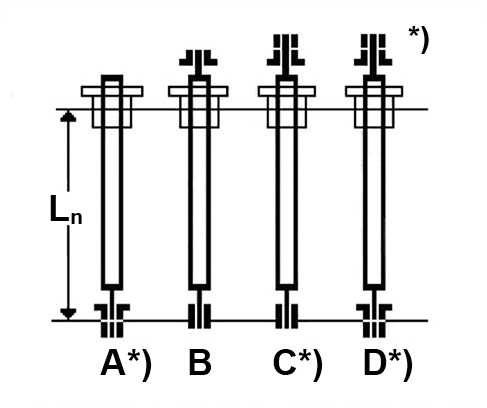

- Nominal diameter d0 [mm]

- Pitch P [mm]

- Ball diameter DK [mm]

- Spindle length Ln [mm]

- Bearing selection: Bearing A, bearing B, bearing C, bearing D

*) Directionally stable clamping

Direct to our service

Your request to us

Use our professional competence to develop the best solution. Our engineers can be reached directly under

+49 2191 989-200

Downloads

In our Download Center, you will find all of the information that we provide you as files for downloading, arranged by category.

Downloads for this Product

ball screws folder 8.94 MB

Ball_screws_Precision_ground_new 0.99 MB

characteristics ball screws 16.00 KB

company profile 478 KB

enquiry ball screws 1.90 MB

telescopic ball screws 7.80 MB

Zertifikat_DIN_EN_ISO_9001 1.49 MB

Direct to our service

Your request to us

Use our professional competence to develop the best solution. Our engineers can be reached directly under

+49 2191 989-200