Overview of Ball Screws for Short-Stroke or Oscillation Applications

The major challenges for a ball screw include applications with short travels (< 5 mm) or applications with oscillating movements. With these movements, the rolling movement of the balls is very small and the ball raceway loads are usually locally stationary.

High Flexibility in Application

The ball screws work almost exclusively here in the range of static friction and boundary lubrication. Since the breakaway torque acts in this work area, these ball screws must be designed to be extremely low-friction. Special ball recirculation systems, special ball arrangements and precisely coordinated running strategies allow for a high level of operational reliability, even with short-stroke or oscillation applications.

Application Areas

Short-stroke and oscillation ball screws are designed for extremely short travels. They are characterized by high dynamics with minimal runways. They offer high operational reliability despite the extreme stationary ball raceway loads.

Practical applications, such as in infeed drives with grinding machines, in plastic injection molding systems or in control systems, have shown that ball screws are also well-suited for this purpose and can successfully be used here. Ball screws that are required for this very demanding task are specially designed for these requirements. High demands are placed on the design, the production and the assembly of the ball screw here. In order to ensure the performance of the ball screw with low infeed movements, the final assembly in the machine environment must also be done very carefully. So that the ball run is not impaired by additional transverse forces, such ball screws should be installed with half the installation tolerance.

The ball screws from A.MANNESMANN for the short-stroke and oscillation application are ideally equipped for exceptionally short travel in long-term application.

Economical advantages

- Lowest cost standard version

- Extremely high speeds

- High peak loads

- Low power loss

- High operational reliability

- Excellent energy efficiency

- High long-term durability / service life

- Maximum long-term precision

- Maximum possible machine availability

- Perfected wear resistance due to nitrided spindle

- Economical standard designs or custom production

Technical advantages

- Very short travels (< 5 mm)

- High dynamics

- Low axial forces

- High system rigidity (< 1,000 N/µm)

- Separating ball

- Single turn or total return

- Special ball recirculation systems

- Special ball arrangements

- Driven nut

- Minimum residual imbalance of the nut body (balancing quality Q2.5)

- Very high specific load

- High production accuracy of the nut

- High precision and efficiency

- High nut rigidity

- Very low idle torque

- Very low frictional torque

- Very low breakaway torque

- The highest power transmission rates

- Extremely high degree of efficiency (up to 98%)

Design

The structural design requires a particularly rigid ball screw with a lowest possible system friction at the same time. So that the system elasticity of the entire feed mechanism does not cover the very small correcting variables of the path, a quick build-up of the distribution of forces from the nut through the balls into the spindle is necessary. The high system rigidity (> 1,000 N/µm) is therefore a basic requirement for the transferability of small paths.

Preload Force

In addition to the selection of the ball return and the ball filling (possibly with separating balls), it is also very important to determine the preload force for the nut rigidity. However, the preload may only be chosen so that the friction does not increase excessively and the breakaway torque in particular remains low.

Accuracy - Tight Tolerances

Ball screws of the accuracy class IT 1 are produced in very tight dimensional, shape and position tolerances. So that the very small ball movements can occur precisely, the surfaces of the ball races must also be machined (polished) after grinding. The same also applies to the transitions of the deflection operations.

Lubrication

Lubrication of the ball screw is also very important for its availability and the achievable positioning accuracy. Since an oil lubrication can achieve the necessary elastohydrodynamic lubrication film at the contact points of the balls better than a grease lubrication, a lower viscosity oil lubrication with an increased lubricant quantity should be used with these applications (if the operating load permits this). It is favorable that no significant operating temperatures occur during small movements and at small speeds and the lubricating oil viscosity largely remains the same.

Positioning Accuracy

The operating conditions that the ball screw must ensure primarily include the masses to be moved. Even if the acceleration is very low here, the mass should be as small as possible so that the acceleration forces also remain low. The selected guide system also affects the positioning accuracy. The lower the friction of the guide, the lower the forces that are required for the displacement and the better the achievable positioning accuracy. In order to achieve the target position of the ball screw as precisely as possible, it is necessary to use a linear measurement system with the corresponding resolution. The rotary encoder system with drive must correspond to the desired accuracy so that a high control quality can be achieved.

The loads for short stroke and oscillation movements are among the most extreme challenges for ball screws. The axial movement is so low here that the balls only cause very minor rotational movements. With oscillation movements, the minor rotational movement occurs very quickly with alternating direction. The balls usually remain at their working point here and load the ball raceways almost stationary, even though the movement speeds may be very considerable due to the high oscillation frequency.

The lubrication is very important to be able to achieve a sufficient operational reliability with these applications as well.

Speed Characteristic Value

The speed characteristic value of dn x n (nominal diameter x speed) < 90,000 applies as a reference value for short-stroke ball screws!

Standards and Custom-Made Production

A.MANNESMANN supplies these precision ball screws for oscillation applications in the nominal diameters of 25, 32, 40, 50, 63, 80, 100 and 125 mm and in the accuracy classes better than IT 5.

Of course as a manufacturer, we also produce special diameters. Please just send us your inquiry.

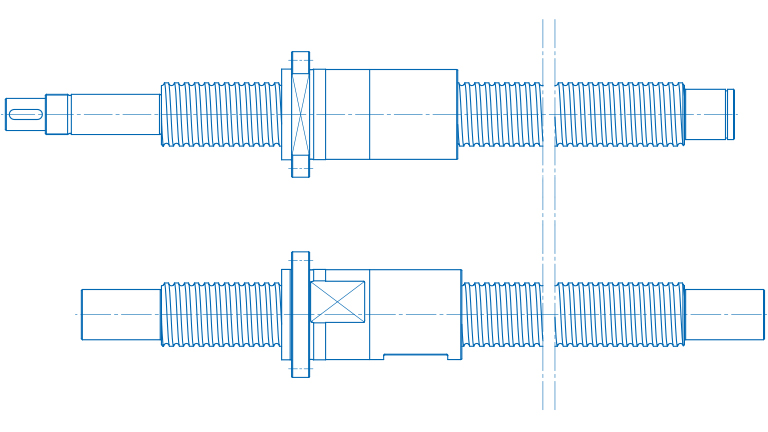

Driven nut and spindle on a ball screw

Characteristic Values of the Ball Screws

In addition to the dimensions, the load ratings, the nut rigidity and the idle torque are the classifying characteristic values of ball screws. The load ratings describe the load bearing capacities of the ball screw during movement (dynamic) and at rest (static). The dynamic load rating is also the basis for calculating the service life.

The nut rigidity is the measure for the axial force, which is required for deformation in the ball transition contact. The idle torque is the characteristic value for the internal system friction. Together with the nut rigidity, the preload can also be closed via the idle torque.

You will find the characteristic values in the technical data sheet of each ball screw.

Rotatory Mass Moment of Inertia

The rotatory mass moment of inertia (Js) of the spindle is usually required for designing the motor. With driven solid spindles, this (with a good approximation neglecting the thread geometry) corresponds to the cylindrical spindle body with respect to its axis of rotation.

Here the ball contact diameter dc on the spindle with the 4th power, the spindle length ls and the density of the spindle material rs are decisive. The mass moment of inertia Js is usually specified in kgcm2. If the rotatory mass moment of inertia Js is related to the spindle length of one meter, then it can easily be converted by multiplying the ratio of the existing spindle length with one meter.

Spindle Torsion

The spindle is normally driven by a motor. The motor's drive torque is guided through the spindle to the nut and there converts into an axial force. In the slim spindle, this results in a torsion due to the torsional moment that exists. The torsion length, the torsion angle and therefore also the torsional rigidity depend on the axial nut position on the spindle. Since this can change variably in operation due to the axial displacement, the torsional rigidity is also not a constant characteristic value.

The maximum torsional stress of the spindle (can usually also be assumed to be a circular full cross-section) can be determined from the torsional moment or torque (T) and from the polar modulus of resistance of the ball screw spindle (Wps) or the spindle diameter.

The torsion angle (torsional angle) is dependent on the spindle length or on the position (I) where the torque acts and on the shear modulus (G) of the spindle material. To calculate the torsional angle, the moment of area of the 2nd order (Ips) and the torsional moment (T) are also required.

Since the effective position (I) varies depending on the axial travel movement of the nut, the torsional angle (j) is also not a constant value, but rather is a function of the length (I). However, torsional angle is also directly dependent on the time variation of the effective torque, whereby it is also to be seen as a function of time. That is why torsional vibrations that temporally vary depending on the torsion are created, which also act in the axial direction through the ball screw.

Tensile and Compressive Load

In addition to the torsional load, a driven spindle is mainly loaded by tension or pressure. In both cases, the tensile or compressive strength of the spindle are the load limit values.

When evaluating the load, it is important to take the correct "smallest" spindle cross section into account. Only the cross-section that lies in the spindle's distribution of forces is relevant for determining the tension. With the tensile load, the determining spindle cross section usually does not lie in the area of the ball screw, but rather in the area of the mounting thread of the bearings. The buckling stability is also to be noted, since there is a risk of buckling in the event of a compressive load on particularly long spindles.

Characteristic Value Calculations

As part of our service, we offer you the calculation of the most important characteristic values. We would like to support you in your planning from an early stage.

Get in touch with us by sending an e-mail to salesamannesmannde with the subject "Characteristic value calculation" or by phoning us at +49 2191 989-0 and give us the following parameters of your desired ball screw:

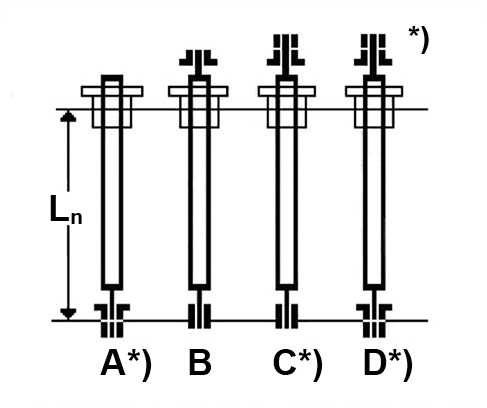

- Nominal diameter d0 [mm]

- Pitch P [mm]

- Ball diameter DK [mm]

- Spindle length Ln [mm]

- Bearing selection: Bearing A, bearing B, bearing C, bearing D

*) Directionally stable clamping

Direct to our service

Your request to us

Use our professional competence to develop the best solution. Our engineers can be reached directly under

+49 2191 989-200

Downloads

In our Download Center, you will find all of the information that we provide you as files for downloading, arranged by category.

Downloads for this Product

ball screws folder 8.94 MB

Ball_screws_Precision_ground_new 0.99 MB

characteristics ball screws 16.00 KB

company profile 478 KB

enquiry ball screws 1.90 MB

telescopic ball screws 7.80 MB

Zertifikat_DIN_EN_ISO_9001 1.49 MB

Direct to our service

Your request to us

Use our professional competence to develop the best solution. Our engineers can be reached directly under

+49 2191 989-200